Silver 20

Reflects heat—and the future

Almost everyone on earth has seen SunGuard® Solar Silver 20. Guardian supplied 167,000 square metres of it for the Burj Khalifa, the world’s tallest building. This reflective glass not only helps architects achieve futuristic designs, it immediately delivers energy savings. The glass reflects heat and solar radiation, making it a great product for hot environments and super-tall buildings.

Product information

- Clear Float 3-12 mm

- Windows

- Skylights

- Facades

- Roof window

- Curtain walls

- Doors

- Heat Strengthened

- Heat Soaked

- Annealed

- Tempered

- Laminated

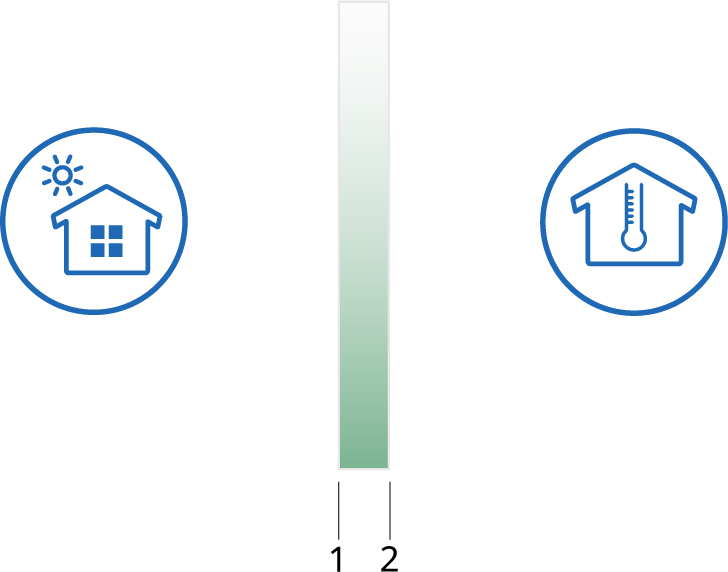

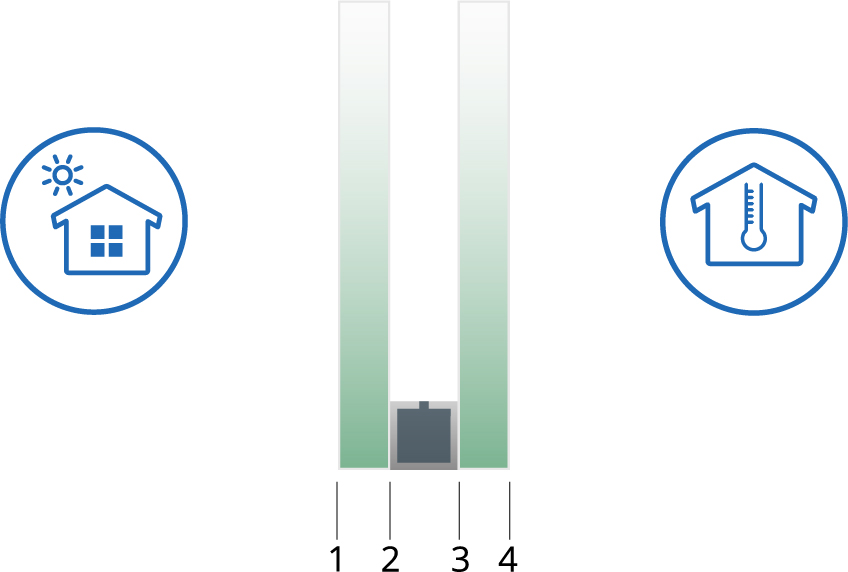

- Surface 2 (double IGU)

- <3210x6000mm

- No

- Durable Coated Glass

- Solar control

- Can be in an Insulating Glass Unit

- Silver

Visual Appearance

Use the Glass Visualizer to get an introductory understanding of how glass will appear in use. Use the Glass Analytics tools to explore even more options for color and performance.

You need more information and additional mockups? Consult our Glass Visualizer Tool:

The glazing make-up suggestions below are pre-defined to provide examples of commonly used combinations of products. There are many other glass combinations available at Glass Analytics.

- Default Performance Data

- Performance Calculations

-

Monolithic

-

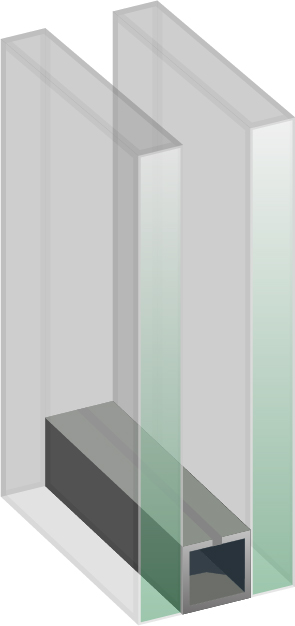

Double Glazed

Monolithic

GLASS: Guardian Clear Glass (Middle East & Africa) Glass, 3/16" (5mm) (2-SunGuard® Solar Silver 20 (Middle East & Africa))

Calculated Values are in accordance with NFRC2010

Performance Values For more details on the performance values displayed and Embodied CO2 please click here

Double Glazed

GLASS: Guardian Clear Glass (Middle East & Africa) Glass, 3/16" (5mm) (2-SunGuard® Solar Silver 20 (Middle East & Africa))

GAP: 10% Air, 90% Argon 12.0mm

GLASS: Guardian Clear Glass (Middle East & Africa) Glass, 3/16" (5mm)

Calculated Values are in accordance with NFRC2010

Performance Values For more details on the performance values displayed and Embodied CO2 please click here

-

Monolithic

Not available for this product

-

Double

Not available for this product

-

Triple

Not available for this product

Monolithic

Monolithic Laminated

Double Glazed

Double Outer pane Laminated

Double Inner pane Laminated

Double Inner and Outer pane Laminated

Triple Glazed

Triple Outer pane Laminated

Triple Inner pane Laminated

Triple Inner and Outer pane Laminated

Access our website on a bigger device to be able to use our comparison tool.

Can’t find the glass make-up you are looking for? Go to Glass Analytics for more detailed configurations:

Find the Guardian Glass supplier nearest you

Add filters