Light Blue 52

A product for blue-sky thinking

Architects trust SunGuard® Solar Light Blue 52 with its uniform light blue color for groundbreaking landmarks, such as the Elbphilharmonie in Hamburg and the Main Tower in Frankfurt. Light Blue 52 can be tempered, heat-strengthened, curved and screen-printed with approved enamels, giving architects flexibility in customising their facade.

Product information

- Clear 3-12 mm

- Windows

- Facades

- Roof window

- Curtain walls

- Doors

- Heat Strengthened

- Heat Soaked

- Annealed

- Tempered

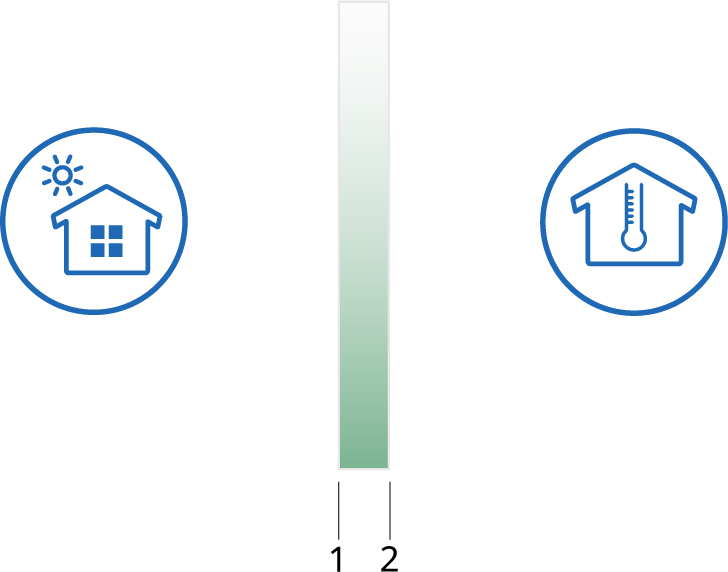

- Surface 2 (monolithic)

- Surface 2 (double IGU)

- Surface 2 (against PVB)

- <3210x6000mm

- No

- Durable Coated Glass

- Solar control

- Can be Laminated

- Can be used Monolithic

- Can be in an Insulating Glass Unit

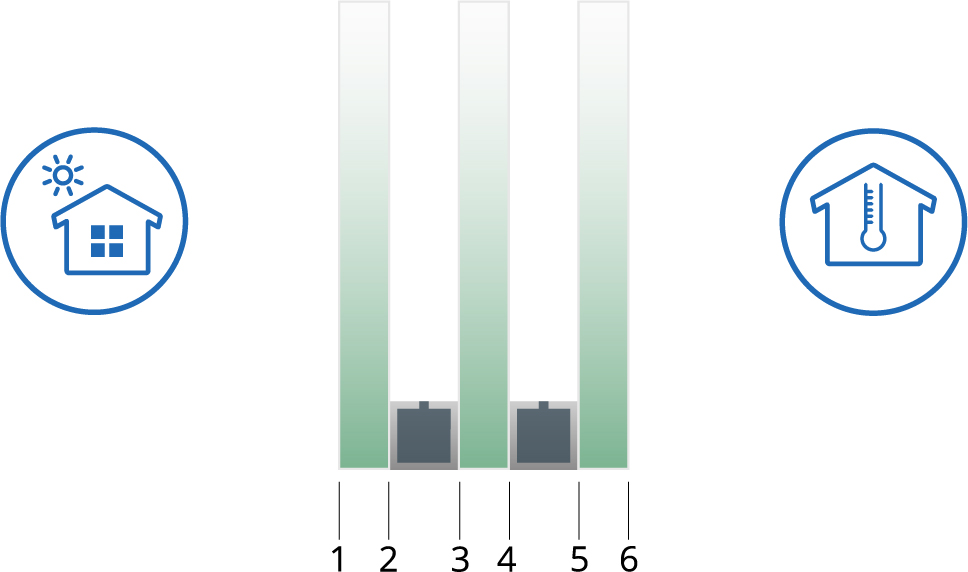

Visual Appearance

Use the Glass Visualizer to get an introductory understanding of how glass will appear in use. Use the Glass Analytics tools to explore even more options for color and performance.

View

This tool intended to represent the reflected/transmitted color ; however, glass color cannot be accurately portrayed online. For more information, launch the Glass Visualizer.

You need more information and additional mockups? Consult our Glass Visualizer Tool:

The glazing make-up suggestions below are pre-defined to provide examples of commonly used combinations of products. There are many other glass combinations available at Glass Analytics.

- Default Performance Data

- Performance Calculations

-

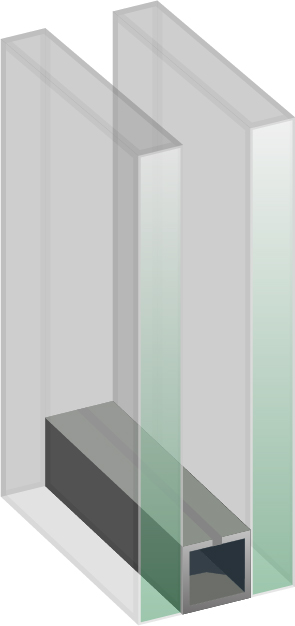

Monolithic

-

Double Glazed

-

Triple Glazed

Monolithic

GLASS: Clear Float (Middle East) Glass, 6mm (2-SunGuard® Solar Light Blue 52 (Middle East))

Calculated Values are in accordance with NFRC2010

Performance Values

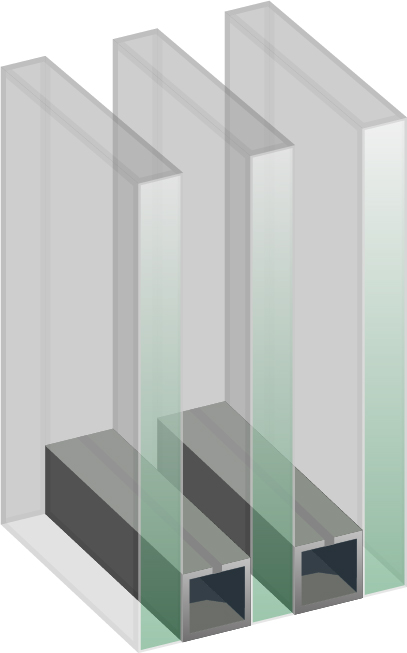

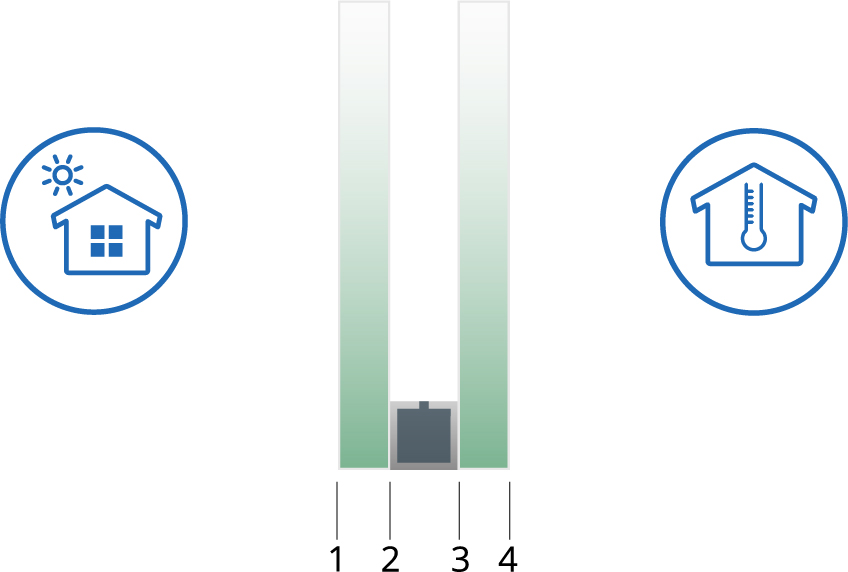

Double Glazed

GLASS: Clear Float (Middle East) Glass, 6mm (2-SunGuard® Solar Light Blue 52 (Middle East))

GAP: 100% Air 12.0mm

GLASS: Clear Float (Middle East) Glass, 6mm

Calculated Values are in accordance with NFRC2010

Performance Values

Triple Glazed

GLASS: Clear Float (Middle East) Glass, 6mm (2-SunGuard® Solar Light Blue 52 (Middle East))

GAP: 100% Air 12.0mm

GLASS: Clear Float (Middle East) Glass, 4mm

GAP: 100% Air 12.0mm

GLASS: Clear Float (Middle East) Glass, 6mm

Calculated Values are in accordance with NFRC2010

Performance Values

-

Monolithic

Not available for this product

-

Double

Not available for this product

-

Triple

Not available for this product

Monolithic

Monolithic Laminated

Double Glazed

Double Outer pane Laminated

Double Inner pane Laminated

Double Inner and Outer pane Laminated

Triple Glazed

Triple Outer pane Laminated

Triple Inner pane Laminated

Triple Inner and Outer pane Laminated

Access our website on a bigger device to be able to use our comparison tool.

Can’t find the glass make-up you are looking for? Go to Glass Analytics for more detailed configurations:

Find the Guardian Glass supplier nearest you

Add filters